This will be a stream-of-consciousness post on my favorite technology right now: the use of gas discharges to transduce acoustic waves into electronic signals. This type of transduction takes advantage of the fact that the electrical resistivity between two electrodes is directly proportional to the gas pressure. The pressure perturbation of an acoustic wave will therefore cause a minute fluctuation of the discharge current if the voltage between the electrodes is held fix. The transduced signal can be extracted simply by high-pass filtering the discharge current. Amplification of the signal is non-trivial. Several efforts have been made to use this transduction mechanism to make a viable "plasma microphone", including patents by Tri-Ergon's Vogt, Engl and Massolle (filed in 1921) and by Westinghouse's Thomas (filed in 1922). The Thomas device used a conventional atmospheric discharge and was used for experimental AM broadcasts but was never commercialized. The Vogt device ("Das Kathodophon") used a thermionic cathode and did see some commercial use in Germany from the late 1920s to late 1930s. There has also been academic research, for example by Fransson et al. in the early 1970s, and more recently by Bequin. The major obstacle to technological viability seems to be that atmospheric discharges are electrically noisy and produce noxious gases (ozone and nitrous oxides).

Instead of revisiting the hard problem of developing a plasma microphone to transduce sound propagating through air, back in 2016 I decided to try to tackle the simpler problem of using a gas-discharge tube to transduce acoustic waves propagating in solids and fluids. Instead of the multiple kV needed for atmospheric discharges, gas-discharge tubes can be operated with voltages as low as 80 V. Their discharges are also much less noisy and obviously noxious gases are not produced by noble gases (neon and argon) confined inside a sealed glass tube! This technology is now becoming mature enough to use and there are patents pending (I'm the inventor, the US patent is assigned to Princeton University). This post is a quick update on the technological development level.

I have been focusing on technical applications, especially the sensing of ultrasound in the frequency range of 60 kHz to 1 MHz. Spontaneous acoustic emissions at these frequencies can be produced when stress energy is released during early stages of metal fatigue. Detecting these acoustic emissions can therefore be used to predict catastrophic structural failure of metal structures (steel bridges, drilling platforms, etc.). Piezoelectric acoustic sensors are used for this application, but they have very limited service life under harsh operating conditions (including high ambient heat and neutron radiation). For the frequency range of interest here, I have found that commodity neon glow lamps make excellent transducers! Here are photos of an NE-2 type neon glow lamp powered off (to the left) and powered on (to the right) with a characteristic glow surrounding the cathode:

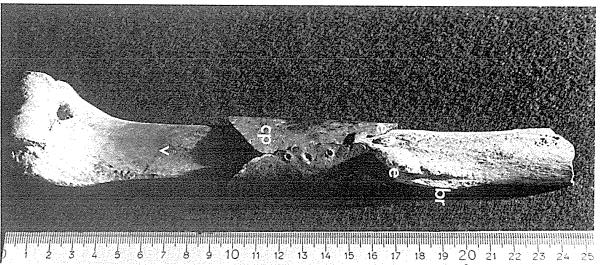

Here's is a comparison of the performance of a similar gas-discharge tube (same 1/4" diameter as the NE-2, but two thirds the length) with a commercial piezoelectric sensor:

As can be seen, the plasma sensor has a much flatter frequency response (that is, its sensitivity depends much less on frequency) resulting in better signal quality. At room temperature the plasma sensor is six times less sensitive at 100 kHz (the primary resonance of the piezo sensor), but six times more sensitive at 600 kHz. In the frequency range of interest, the plasma sensor sensitivity is within a 6dB range and most of that variation is probably due to the ultrasound transmitter used for the testing. Interestingly enough, for this test the plasma sensor performed better at 150 degrees Celsius than at room temperature with a factor of 2.5 increase of sensitivity. Here's is the same plot on a log scale: